The engineering story

After 25 years, a new era begins.

Pioneering radical change.

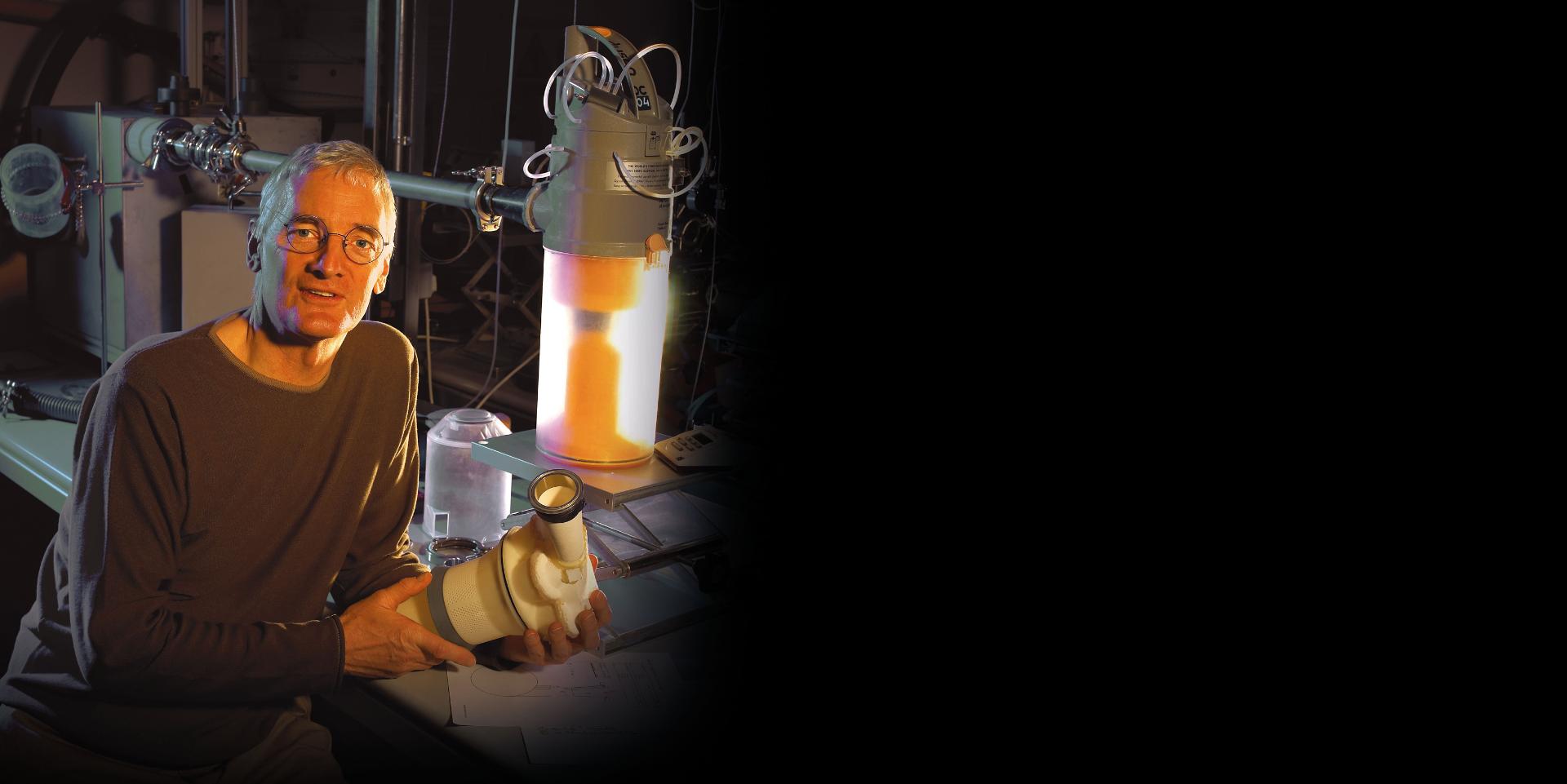

Frustrated by dust clogging the bag of his vacuum cleaner at home, James Dyson spent five years and 5,127 prototypes inventing the world’s first cyclonic vacuum cleaner. Launched in 1993, the DC01’s revolutionary technology solved the everyday problem of vacuums losing suction. Since that first Dual Cyclone, Dyson has continued to break new ground – inventing a cordless vacuum cleaner that has the constant powerful suction of a full-size

Smaller, faster, lighter.

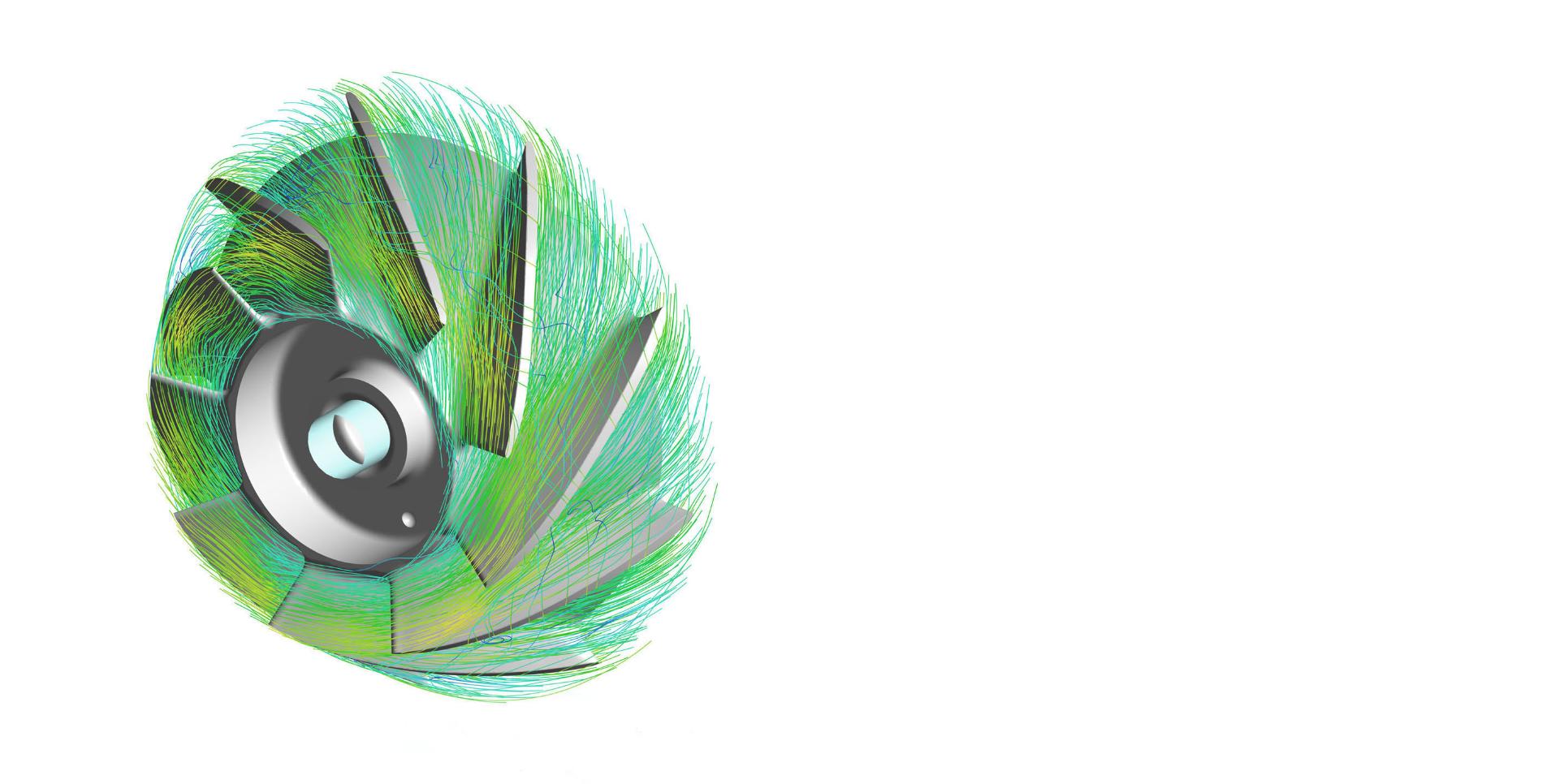

Our engineers looked to aerospace engineering to create a motor that delivered the power we needed. The case material is phenolic moulding compound – as used in satellites – for its high resilience and strength-to-weight ratio, to smooth vibrations at ultra-fast motor speeds.

Increased efficiencies.

A Polyether Ether Ketone (P.E.E.K) and carbon fibre composite, found inside high-intensity pistons, was used for the impeller. To help channel more airflow, we overlapped the impeller’s vanes, creating a larger surface area and improving efficiency.

Ceramic centre.

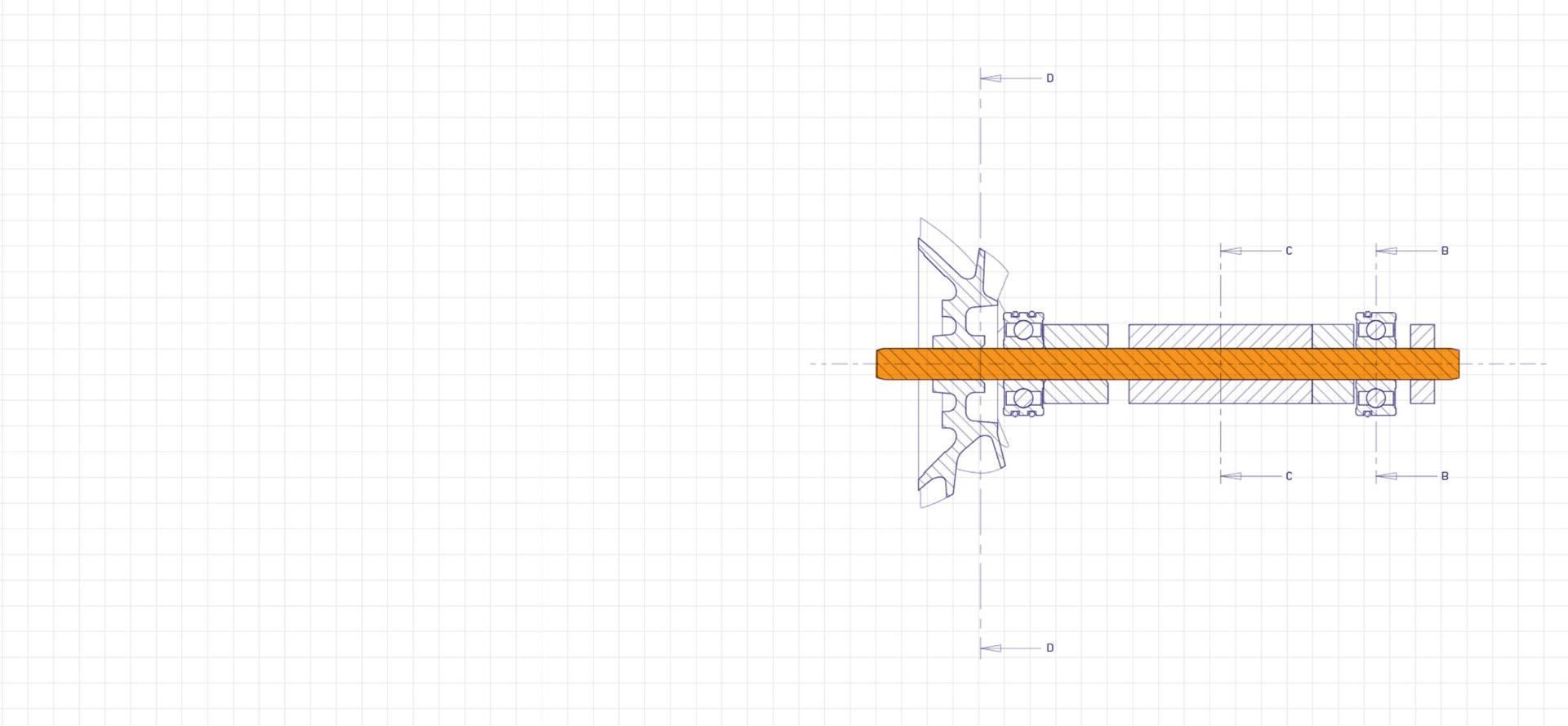

The motor needed a light, strong shaft that was able to cope with speeds of 125,000 rpm. Such high speeds create intense heat, causing a steel shaft to develop a curve of 10 to 20 microns – a tiny deviation, but enough to cause disruptive vibrations. So we used ceramic, which is cured at 1,600°C and three times harder than steel, at exactly half the density.

The boing effect.

Because of the extra power of the Dyson V10 motor, Dyson engineers had to double the number of magnet and stator pairs. When the trigger is released, the motor brakes the rotor to a stop almost instantly and the magnets bounce between the four stator positions. Like a ping-pong ball bouncing on a table, they move a smaller distance each time, creating a sound which our engineers call the ‘boing’.

The Dyson digital motor V10.

The result of all this development was the Dyson digital motor V10 – the fastest digital motor we have ever created.

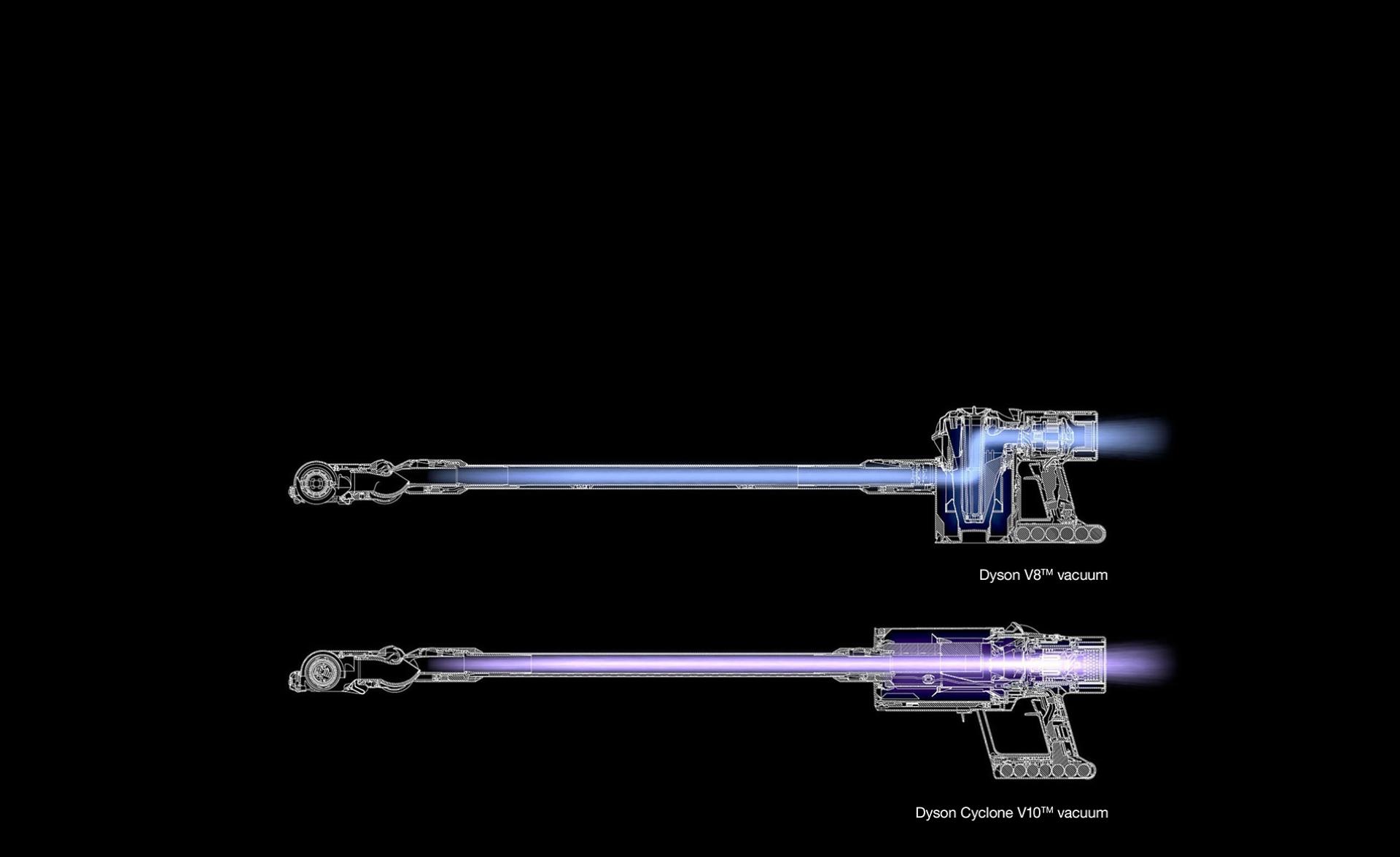

Direct development.

This smaller motor allowed our engineers to rotate the cyclone and bin assembly through 90 degrees, into an in-line format. This created a linear airflow path – improving the number of Air Watts of suction by 20% compared to Dyson V8™ vacuums and allowing a ‘point and shoot’ bin emptying mechanism.

Advanced filtration.

It also allowed us to wrap both the pre- and post-motor filters around the motor as one sealed unit, for improved filtration. We improved the motor housing, adding sound-absorbing material and acoustic baffles, to reduce noise.

Long-lasting power from a single battery.

We wanted to get long-lasting suction power into just one battery, our seven-cell, 525 Watt lithium-ion battery pack has high-capacity which delivers fade-free power using nickel-cobalt-aluminium battery chemistry. Dyson’s intelligent power management system monitors power distribution to deliver fade-free power.

Game changer.

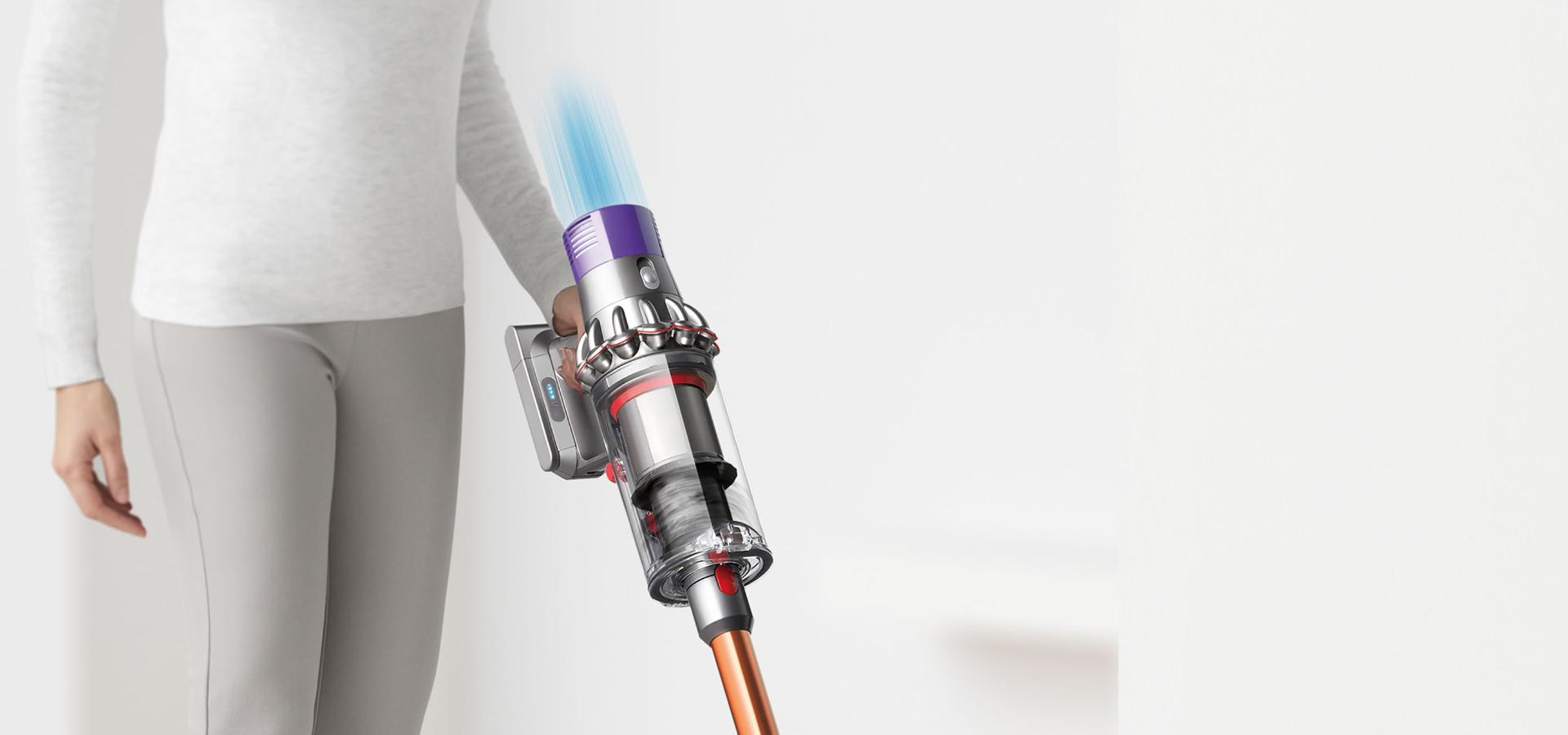

We’ve come a long way in 25 years – we’ve reinvented the cordless vacuum cleaner to have the suction power of a corded vacuum.¹ Now a new era begins.

The Dyson Cyclone V10™ cordless vacuum.